Pipe and Profile Galvanized Coating

Pipe and Profile Galvanized Coating

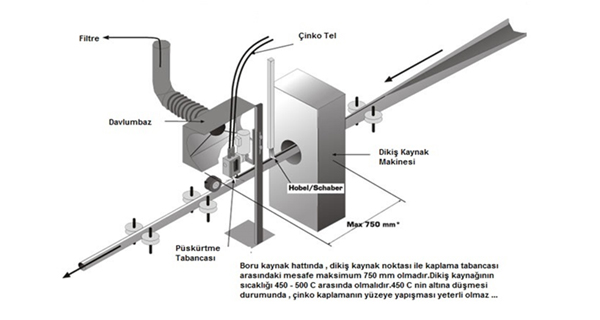

It is the process of coating the seam welding areas of pipes and profiles made of galvanized sheet with the spray zinc method. With the Arc Spray devices produced and designed for this system, it is possible to obtain a high quality surface at low cost. With the specially designed spray gun, low consumable consumption and continuous spraying process that does not interfere with production takes place.

As with all steel structures in atmospheric environments, corrosion is an issue that needs to be addressed.

Metal spraying is commonly used to alter surface properties such as providing corrosion protection to ferrous metals, increasing the wear resistance or thermal conductivity of the sprayed items.

What are spray galvanizing versus hot dip galvanizing?

Galvanizing is a well established process for corrosion of steel. In practice, the steel material is dipped briefly in molten zinc and the coating deposits very quickly. Galvanized sheets are generally of equal thickness, dense and metallurgically bonded to steel.

Metal spraying offers the following advantages over galvanizing;

- Low heat input while spraying eliminates the risk of thermal degradation

- Low heat input eliminates the risk of thermal metallurgical degradation

- In closed pressure vessels, the process is carried out without the risk of explosion.

- Coating is not limited to zinc only, Aluminum, Steel, Copper etc. takes place in coatings. It is an environmentally friendly practice and there is no waste.

- Coating thickness can vary from place to place to provide extra protection in critical areas

- No limitation in material size

- No waste disposal problem

- Reduced zinc stocks are required. Working capital does not depend on molten zinc bath like hot dip galvanizing.

- No fuel is required to keep the zinc melted when the process is not running

- Metal spraying is applied to restore corrosion protection in damaged areas of welded galvanized steel.

Copyright by Ark Sprey Kaplama Cihazları. All rights reserved.